The Technology

Our High Temperature Superconducting Mass Driver (“Quench Launcher”) holds the promise to dramatically transform launch cost. Other technologies have been explored, but each has critical defects that has made them a failed strategy for a robust high velocity mass driver.

EML’S HTS LAUNCHER

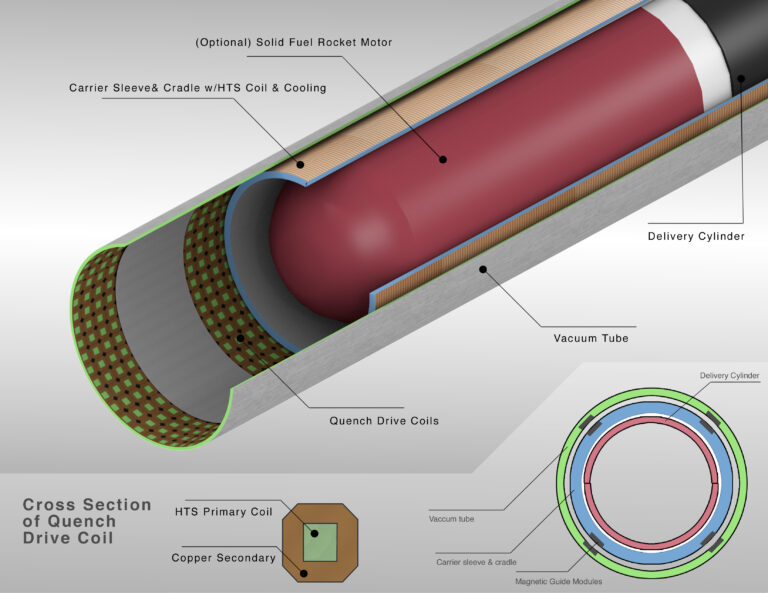

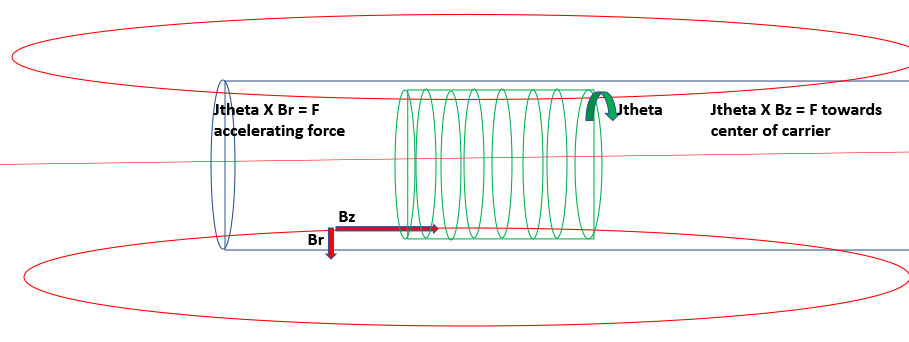

A high velocity mass driver capable of moving a large amount of mass requires extremely high magnetic fields. High magnetic fields result from high current density in the coil windings. High current density levels, enabled by high-temperature superconductors, circulate in the outer rings (stators) along the vacuum tube. This creates ultra-high magnetic fields that pull the carrier sleeve (armature) with its delivery cylinder forward. This simple electric motor configuration is commonly known as a solenoid. The key technology at EML is our patent pending switching technology that quenches or turns off each stator as the carrier sleeve and delivery cylinder pass by.

Our patent pending quench motor design turns off or quenches as the launch package approaches the center. Importantly, it is a non-contact design, with a central carrier sleeve (acting as the armature) supported magnetically. All the quench launcher’s coils are powered up the entire length of the launch tube prior to launch and are therefore both the drive mechanism and energy storage device.

The devil lies in the dynamic details of the rapidly changing fields as the carrier sleeve accelerates forward, and of course, in the performance of quench switching.

The simple diagram below describes the general drive field layout. As the carrier sleeve (armature) moves forward in the launcher the currents in both the launcher (stator) coils and the armature coils are changed by magnetic interaction with each other.

For more information on the Quench Launcher see the Q & A section.

HOW IT WORKS

FAILED ELECTROMAGNETIC LAUNCH TECHNOLOGIES

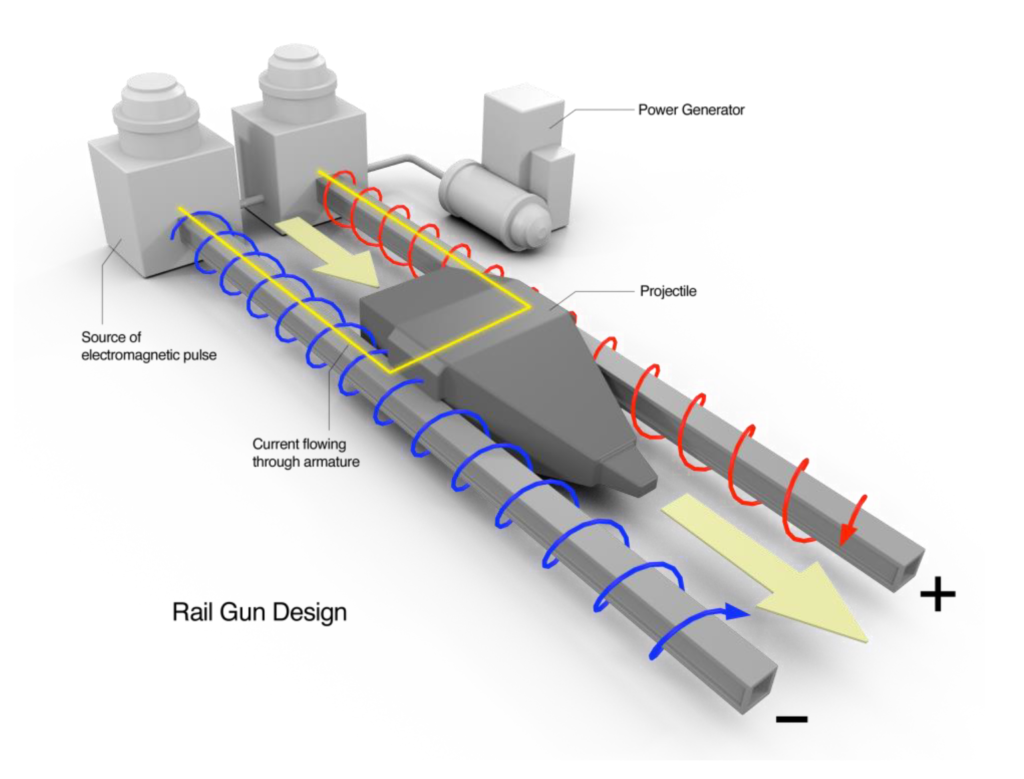

The Rail Gun

The rail gun is the simplest of all the designs, it is a projectile (armature) located between two rails. As power flows from one rail, through the projectile, into the other rail, a force, known as the Lorentz Force, pushes the projectile forward.

Critically, the rails and the projectile need to be in physical contact for the system to work. And the system is inherently low in efficiency. The energy that does not become motion, tends to become heat. At high power levels and high speeds, the arcing, plasma, and wear create limits on the number of times such a launcher can be used without needing to be rebuilt. Further, the detritus from the rail projectile interaction causes a “restrike” or new conductive path between the rails behind the armature robbing power and limiting higher velocities.

It was originally selected because it does not require the high speed high current switching problem to be resolved.

After review, the DoD quietly shuttered their research effort into high power and high-speed rail guns as the issues with robustness at high power levels and high speeds were found not to be resolvable.

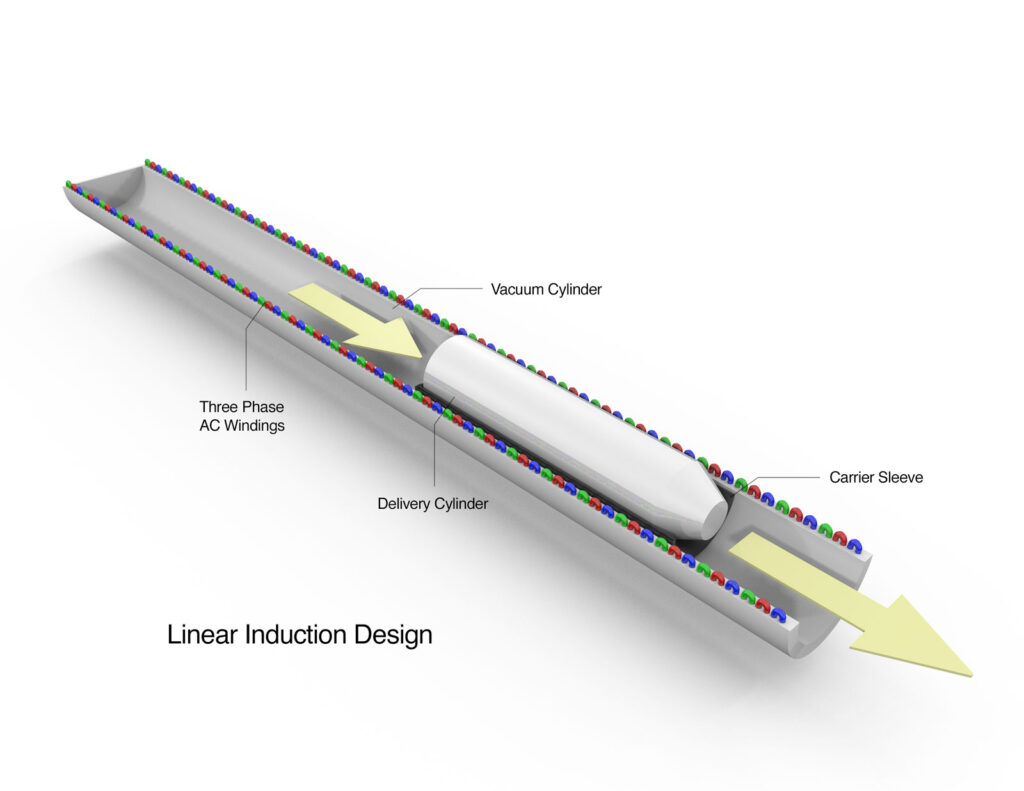

The Induction Launcher

This technology is the basis of most electric motors today, including linear electric motors that could be used in a launcher. Also known as traveling wave launchers, the armature moves along in front of the EM wave like a surfer. At higher and higher frequencies, the armature moves faster and faster.

Unfortunately, again, there is no known way to switch very high current levels at very high frequencies necessary to reach high velocities.

In general, this is known as “the switching problem” and is common to all non-contact electromotive methods.

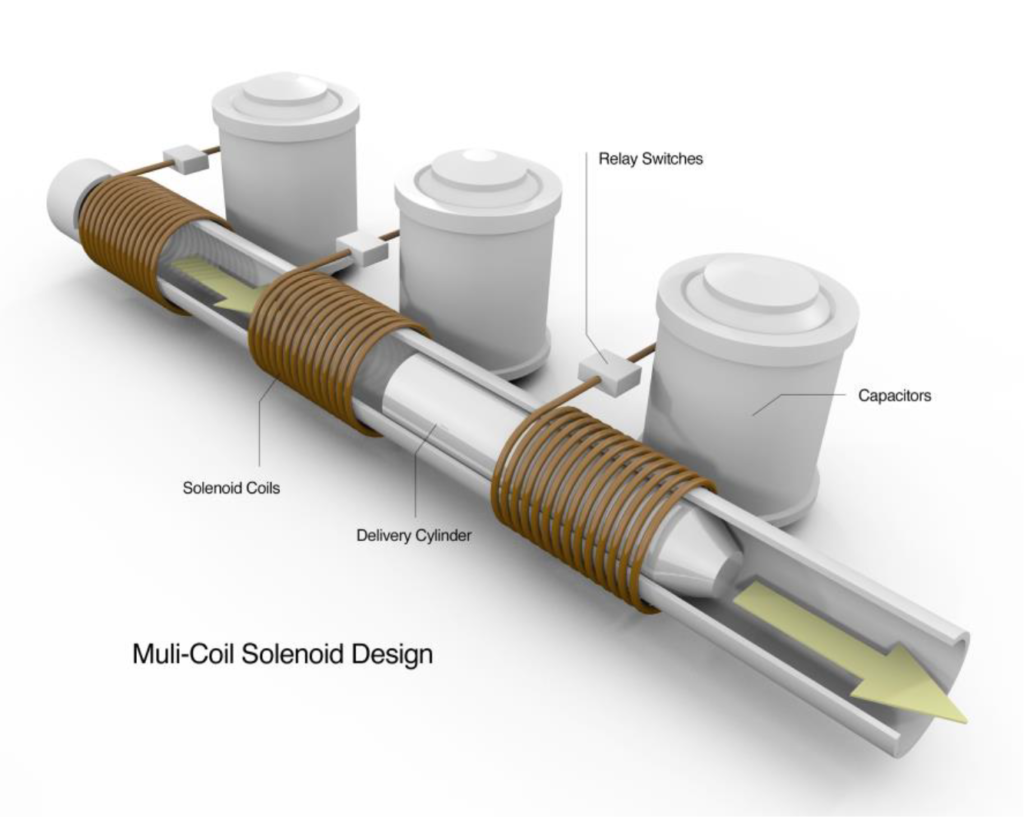

The Coil Launcher

A series of coils, if energized at exactly the right time, could push a launch package forward, each giving another boost to higher and higher velocities. First, it is difficult from a materials science perspective to aggressively push a long and small-diameter object without risk of collapse. (Pulling is better.)

Power needs to be stored so that it can quickly dump into each coil exactly when needed. Many hundreds of giant capacitors or ultra-capacitors might suffice. As with the Induction or Traveling Wave Launcher, the switching problem has been shown to be insurmountable at high current levels and velocities.

Finally, when designed as a resistive (not super conducting) solution they system has low efficiency as a matter of physics. The greater the current dumped into the coils the greater the resistance. This is both from heating and inductive resistance. This is a fundamental physics problem and is not resolvable by engineering.