Economics

ECONOMIC ANALYSIS

The economic projection below is for an earth based launcher. A lunar system, with an ever present vacuum, cold and dramatically reduced need for Delta V would have lower operating costs. Shipment cost of raw materials to lunar orbit, Lagrange points, Mars and Earth orbits for a Moon based system appear to be almost negligible for a solar powered non-contact quench launcher. Most operating cost would derive from small rocket motors with guidance packages and those costs would be highly dependent on subsequent capture for reuse.

The Earth launch projection is calculated to produce an all-in operating cost model and is based on listed assumptions. Our critical measure is cost per pound to low Earth orbit. The values used were judged reasonable by experts involved but are highly sensitive to exit velocity and robustness of operation.

Excluded are the substantial up-front capital costs provided in an assumed public and private partnership, ongoing research and development costs, external security costs and taxes. An automatic loading quench launcher design is assumed with robust performance requiring only minimal inspection maintenance for this magnetically levitated system. Related necessary operations such as maintenance of vacuum, cooling, loading and exit door (and exit membranes if needed) are included as shown. Fitment of nose cones and solid rocket motors are also included. Production of Nose Cones and rocket motors are included as outside purchases. Operation in a remote location is assumed.

SPECIFICATIONS FOR ECONOMIC ANALYSIS

- Launch Tube length: 17 km evacuated composite (15 km acceleration and a 2km deacceleration)

- Launch Tube I.D.: 1.2m

- Launch angle: 15 degrees.

- Launch elevation: 3,500m

- Acceleration = 8 sec at 79

- Gs to 5.6 km/s at exit

- Diagonal bore depth (for sunk portion): 900 meters

- Delivery Cylinder: 1m by 7.5m

- Solid fuel rocket motor 1m by 7.5 m

- Delivery Cylinder + SFRM mass: 35,400 Kg (based on 3x water)

- Carrier Sleeve Armature

- I.D.: 1 m by 15m

- Carrier Sleeve Armature O.D.: 1.2 m by 15m

- 250s impulse solid fuel composite sleeved rocket motor for delta V

- Carrier Sleeve Mass: 15,500 Kg (based on 3x water)

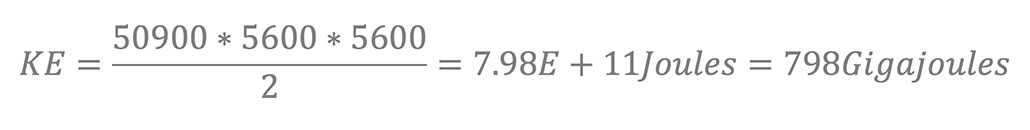

- Carrier Sleeve + Delivery Cylinder + SFRM: 50,900 Kg

- Orbital Velocity Required = 8km/s

- Magnetic field: B = 10.8T

- Exit velocity: 5.6km/s

- Launch cadence: 8 times per day, six days per week

POWER GENERATION ECONOMICS

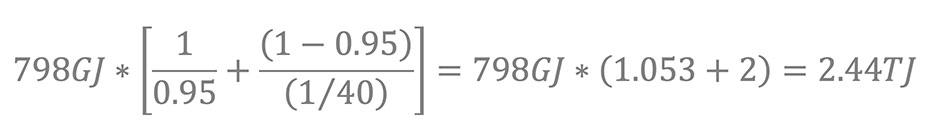

The power generation economics assume the continuous charging capability of the launch tube, a key benefit of the storage capability of a quench launcher design. It assumes high efficiency for the launcher and very substantial energy use for cooling to 30 degrees K (to allow for highest performance of the HST’s) along with power for vacuum maintenance and related facilities.

Given a location in a remote location, analysis showed solar with utility scale storage as a lowest cost approach. In practice, this may well be best augmented with wind turbines and back up gas generators. Or possibly, entirely replaced by one of the new generation Small Modular Reactors. For simplicity, this study only considers solar generation. The large solar array required would be one of the top ten existing solar arrays already in use by size.

All other power, including significant cooling, vacuum maintenance, and facilities is estimated to be equal to that of the launch power requirement. Operating costs for power generation are based on data as confirmed by NREL (The National Renewable Energy Laboratory) Operating costs for a utility scale system are broken into fixed and variable operating maintenance costs (FOM and VOM). NREL estimates variable operating costs at near zero, with fixed operating costs at 2 ½% of CAPEX, and can be managed at purchase though warranty agreement.

LAUNCH POWER REQUIREMENTS: (AT 5.6 KM/S)

COOLING POWER REQUIREMENTS: (TO 30 DEGREES KELVIN)

Based on 35% of Carnot efficiency to 20 degrees Kelvin

FULL POWER CALCULATION OVERVIEW HERE

DELIVERY CYLINDER MANUFACTURING & LOADING EXPENSES

The composite delivery cylinder itself is considered a deliverable to LEO. Users of the launch system are expected to provide raw materials in cylinders to EML launch specifications. Re-use or up cycling of composite materials on orbit is a key unsettled economic issue.

NOSE CONE AND ROCKET MOTOR EXPENSES

OPERATIONAL STAFF REQUIREMENTS

EXECUTIVE TEAM

CEO

CFO

VP Operations

VP Quality Assurance

VP H/R

VP Communications

Administrative Assistants (3)

Six Executives + three admins = $2.5m / yr.

DIRECTORS

Security

Logistics

Information Technology

Launch Operations

Facilities Operations

Quality Assurance

Launch Inspection and Maintenance

Facilities Inspection and Maintenance

Vendor and Raw Materials

Corporate Controller

Ten directors plus three admins = $2.5 m / yr.

OPERATING STAFF

10 Logistics, Purchasing, Accounting

15 Loading and component assembly

4 Information Technology

20 Security (non-DoD)

20 Quality

10 Fire Control

10 Power Generation

10 Vacuum Generation

10 Cooling

20 Maintenance

20 Facilities and residence support

149 Operating Staff = $19m

Total estimated staff cost = $24m per year

TRAVEL, EXECUTIVE OFFSITE SPACE LEASE, AND MISC. EXPENSES

3,500 square feet, Austin area at $250,000 per year

Travel, to remote site, and as needed (10 person trips / week x $2,000 per trip / 50 weeks per year) $1,00,000 x 2 for private aviation for trips to / from remote location) Other misc. expenses $1,000,000 + per year. Total = $4,000,000

EXCLUDED OVERHEAD EXPENSES

Capital Costs as a necessary and federally funded “public good” project.

Depreciation & Amortization

Interest Expense

Security (DoD)

Taxes

COMMENTS

Loss of .5 km/s from friction is added to the required 8.0 km/s Delta V

The typical specific impulse from a solid propellant is 220-280 s depending on propellant. Corresponding ideal nozzle exit velocities are 2150-2740 m/s, ignoring gravity, this gives propellant mass/launch mass = 1exp (Delta_v/exhaust_velocity). Based on simulations run in Octave the amount of solid fuel is increased in weight and cost from the initial specification by 50%. Minimal communications, guidance, and control equipment, although presumed to be necessary, are an assumed, not a calculated, value in this projection.

OPERATING COST SUMMARY

Full Capacity to LEO = 93,456,000 pounds / year (38,940lbs x 8/day x 6 days / week x50 weeks)

½ Capacity to LEO = 46,728,000 pounds / year

Staff Operating Staff Costs = $24,000,000 / year (Treated as fixed costs)

Electrical Generation Maintenance Cost = Warranty cost at time of purchase + staff as listed

Composite Solid Rocket Fuel (5.6 Km/s exit) = $75,000 / launch ($90m to $180m /year)

Communication, guidance, control kit = $20,000/ launch ($24m to $48m / year)

Listed consumables per flight = $11,000 / launch ($13.2m to $26.4m / year)

Misc. Expenses = $4,000,000 / year

Total Op Expense at Full Capacity = $282,400,000 per year or $3.02 per pound

Total Op Expense at ½ Capacity = $155,200,000 per year or $3.32 per pound

CRITICAL UNANSWERED QUESTIONS IN THE ECONOMIC ANALYSIS

- Can the system achieve 5km/s? (Or 6km/s, or 7km/s, or more?)

- Can they system run repeatedly with little or no repair?

- Might a launch mass of ½ the estimated amount but with twice the cadence be preferable?

- Might the launch tube need to be twice as long, or more, to reduce stresses to the point where low-cost repeat use goals are met?

- Can empty delivery cylinders and rocket motors be recycled or upcycled on orbit effectively?

SUMMARY OF FINDINGS

An examination of the potential economics underscores the possibility, even at a multiple of the estimated cost, that a quench launch system has the capacity to transform the economics of delivery to low earth orbit. The value to a space economy of a regular low-cost delivery service probably can’t be overstated and is comparable to the value of a highway or railroad system to a modern economy.